|

|

AOI X1 Offline Inspection SMT Pick And Place Equipment SMT Assembly Machine

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | AOI Testing Equipment | Model: | SZ-X1 |

|---|---|---|---|

| Camera: | Full Color Smart Digital Camera | Thickness Range: | 0.5~5.0mm |

| Maximum Maximum PCBA Weight: | 3kg | PCB Size Range: | PCBA Cur Vature |

| High Light: | AOI Smt pick and place equipment,Offline Inspection SMT Assembly Machine,AOI SMT Assembly Machine |

||

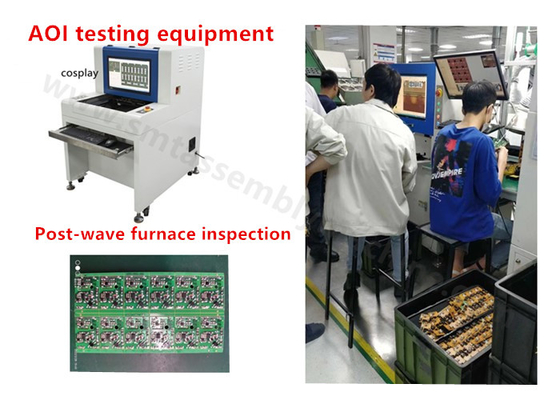

Smt pick and place equipment AOI X1 Offline inspection for SMT Assembly Machine

There are four main settings in the program settings:

1). Coordinate origin PCBA board for detecting SMD

The coordinate origin is the datum point of the component coordinates,

and the lower left corner of the board must be set as the coordinate origin.

Machine testing is to find the position of the component with the coordinate origin as zero,

and the coordinates of the coordinate origin are relative to the machine origin.

The machine origin is set when the machine leaves the factory. The machine origin of each machine is different,

when the program programmed on one machine is copied to another machine,

only the coordinate origin of the program needs to be reset.Yamaha accessories

2). PCB board size: The PCB size can be measured in the upper right corner of the PCB.

3). Application mode Post-wave furnace inspection

Step: Move the center of the cross (the center of the lens) to the lower left corner of the PCB,

so that the cross includes the PCB, click [Current Position] of the surface origin in the pop-up window,

the system will automatically calculate the coordinates of the current cross center, Detection of PCBA products

the same is true to move the center position of the cross to the upper right corner of the PCB,

click the "Current Position" of the PCB size to record the PCB size. Once defined, click (Next).

Function parameter

| SZ-X1 Product Specification | ||

|

Imaging System |

Camera | 5 megapixel high definition intelligent industrial camera |

| Camera resolution | Standard configuration:15um/PixelFOV:38.0mm*30.0mm;Optional:20um,10um | |

| Light source | RRGB high gray LED light source | |

![]()

Contact Person: Leo Huang

Tel: 18665307937

-

AOI SMT Inspection Machine Full Color CCD Camera Networkable Remote Operation

-

AOI Surface Mount Machine SZ-X1 0201 0402 0805 PCB Inspection System

-

AOI SZ-X3 Versatile optical inspection machine For Measure Welding Effect Of DIP Silver Feet

-

Offline Versatile AOI Inspection Machine SZ-X3 Software Function Image Comparison High Pass Rate

-

Offline Machine AOI SZ-X3 Post Welding Electronic Board Short Circuit Check

-

Plug In AOI Inspection Machine DIP Offline SZ-X3 Check PCB Size Max 430×330mm